BUSINESS

5 sides surface machining center

It is suitable for processing large-sized mold, aircraft parts, and LCD related products with its excellent structure of powerful cutting and high accuracy, and maintains high precision even for long time of operation.

MCV 1630 Superior structural design delivers the best power cutting and precision machining in its class!

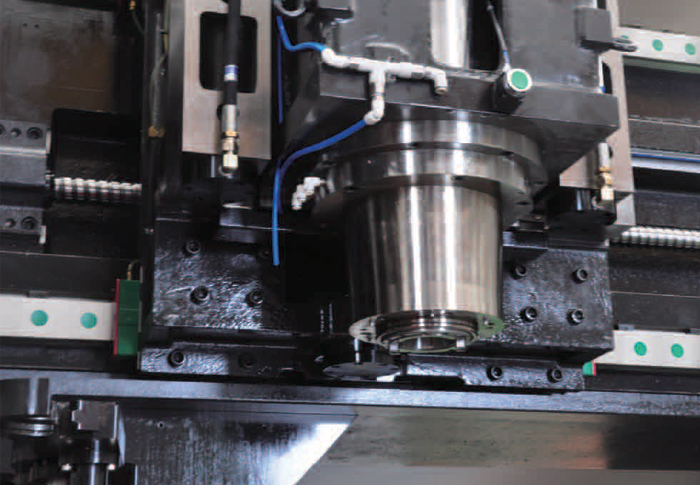

High rigidity spindle structure of the same model

Spindle of BBT50 12,000 rpm with built-in motor of wide area constant power speed range and high-torque, and with Гҳ100, 4 row P4 class high precision bearings, so that it maintains accuracy in a consistent way even in the long time operation.

Centralized Control Panel

The centralized control panel of the 10.4 "TFT LCD monitor is capable of turning up to 180В°, enhancing operability and convenience during the operation.

Specifications

| Transfer Volume(X/Y/Z) | 3,200 / 1,600 / 800mm |

| Maximum Loading Weight Per Table | 10,000kg |

| Surface Machining Size Per Table | 3,000(3,300) Г— 1,500mm |

| Rapid Transfer Rate(X/Y/Z) | 24 / 24 / 16m/min |

| Motor of Transfer Axis(X/Y/Z) | 7 / 7 / 9kW |

| Maximum Speed of Spindle | 12,000rpm |

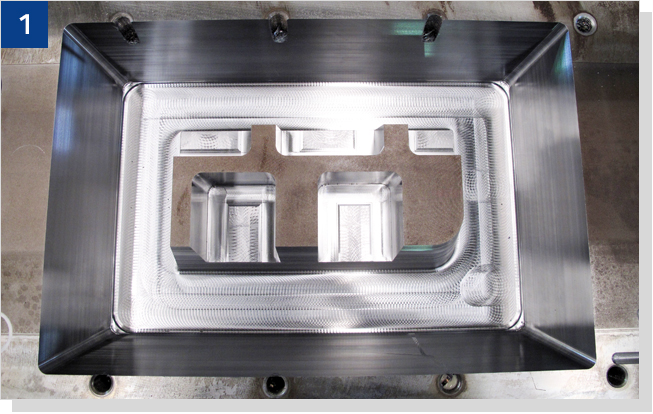

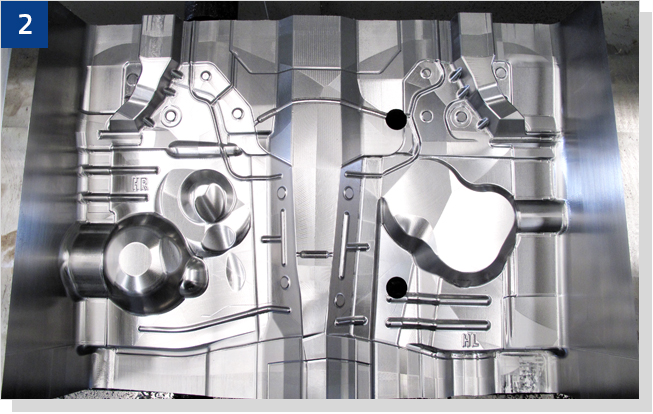

Automotive Mold Processing Cases

- Tool : Гҳ26 F 0.8R, Spindle : 2,700rpm, Feedrate : 3,500mm/min

- Tool : Гҳ25 ball, Spindle : 4,000rpm, Feedrate : 3,500mm/min

- Frame-Tool : Гҳ26 ball, Spindle : 4,500rpm, Feedrate : 3,200mm/min, Shape-Tool : Гҳ10 ball, Spindle : 6,500rpm, Feedrate : 2,800mm/min, Materials : HP4M